1. سنگ شکن مخروطی هیدرولیک تک سیلندر ویژگی های عملکرد

الف) راندمان بالا: سنگ شکن مخروطی هیدرولیک در انتهای بالایی و پایینی شفت اصلی دارای تکیه گاه هایی است که می توانند نیروی خردایش و ضربه بیشتری را تحمل کنند و شکل حفره خردایش ویژه سازگار با اصل لایه بندی، دستگاه را از راندمان خردایش بالاتری برخوردار می کند.

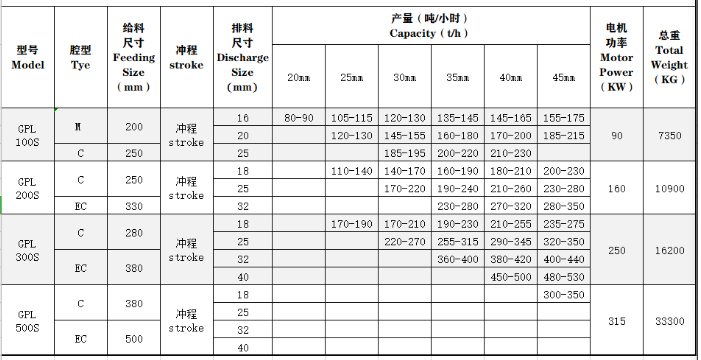

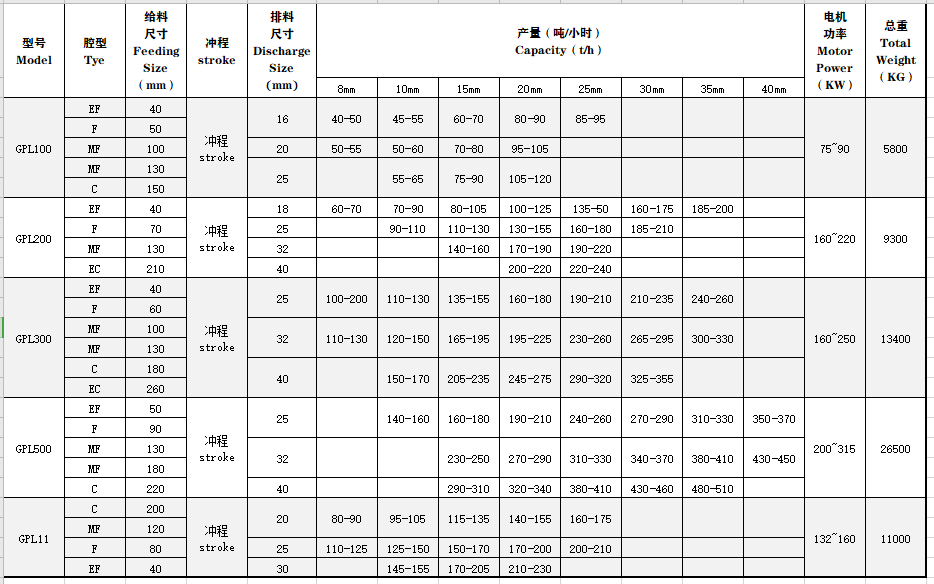

ب) ظرفیت تولید بالا: سنگ شکن مخروطی هیدرولیک با ترکیبی کامل از ضربه خردایش، سرعت خردایش و شکل حفره خردایش طراحی شده است، به طوری که خروجی دستگاه 35٪ ~ 60٪ بیشتر از سنگ شکن مخروطی فنری قدیمی است، زمانی که قطر انتهای بزرگ مخروط متحرک یکسان است.

ج. سنگهای با کیفیت بالا: سنگشکن مخروطی هیدرولیک با شکل منحصر به فرد حفره خردکننده و اصل خردایش لایه لایه، اثر خردایش بین ذرات را ایجاد میکند، به طوری که نسبت مکعبها در محصول نهایی به طور قابل توجهی افزایش مییابد، سنگهای سوزنی شکل کاهش مییابند و ذرات کاهش مییابند. سطح یکنواختتر است.

د. خردایش متوسط و ریز حفرههای با اشکال مختلف را میتوان تنها با تعویض مخروط ثابت انجام داد.

ه. سیستم هیدرولیک و روانکاری که توسط بیمه مضاعف کنترل میشود، میتواند محافظت در برابر اضافه بار دستگاه و روانکاری خوب یاتاقان را تضمین کند.

و. نگهداری آسان: سنگ شکن مخروطی دارای ساختار ساده و جمع و جور، عملکرد پایدار و عدم خرابی آسان است. تعمیر و نگهداری آن راحت و سریع است.

2. سنگ شکن مخروطی هیدرولیک تک سیلندر هدف

برای خردایش مواد اولیه در صنایع متالورژی، ساخت و ساز، راه سازی، شیمیایی و سیلیکات مناسب است. این دستگاه میتواند سنگهای معدنی و سنگهای مختلف با سختی متوسط و معمولی را خرد کند. سنگ شکن مخروطی هیدرولیک دارای نسبت خردایش بزرگ، راندمان بالا، مصرف انرژی پایین، اندازه یکنواخت محصول، مناسب برای خردایش متوسط و ریز سنگهای معدنی و سنگهای مختلف است.

3. سنگ شکن مخروطی هیدرولیک تک سیلندر اصل کار

موتور، چرخدنده کوچک سنگشکن را به حرکت در میآورد، چرخدنده کوچک، چرخدنده بزرگ را به حرکت در میآورد و اجزای چرخدنده بزرگ (چرخدنده بزرگ، قاب چرخدنده بزرگ، غلاف فولادی خارج از مرکز) اجزای غلاف خارج از مرکز (غلاف سیلندر خارج از مرکز، غلاف مسی خارج از مرکز) و اجزای شفت اصلی (شفت اصلی، مخروط داخلی)، بوش مخروطی داخلی) را که روی خط عمودی فرضی متمرکز شدهاند، به حرکت در میآورند. این غلاف در بوش مسی خارج از مرکز روی خط مرکزی اسپیندل میچرخد. هنگامی که دستگاه خالی کار میکند، مجموعه غلاف خارج از مرکز، مجموعه شفت اصلی را نگه میدارد و با چرخدنده بزرگ میچرخد. هنگامی که مواد به محفظه خردایش اضافه میشوند، مجموعه شفت اصلی (اسپیندل، مخروط داخلی) به آرامی در غلاف مسی خارج از مرکز تحت مقاومت چرخش مواد حرکت میکند. به نظر میرسد مسیر حرکت مخروط داخلی در حین چرخش آهسته در حفره خردایش به جلو و عقب نوسان میکند. مواد توسط مخروط داخلی در حال نوسان خرد میشوند. اتصال بین غلاف نگهدارنده و بدنه قاب توسط یک سیلندر هیدرولیکی فشرده میشود. مخروط متحرک تک سیلندر توسط پیستون هیدرولیکی در پایین نگه داشته میشود وقتی یک بلوک فلزی یا سایر اشیاء نشکن به داخل سنگ شکن میافتد، که میتواند دریچه تخلیه را تنظیم کرده و از عبور آهن محافظت کند. برای از بین بردن نقش انسداد، بالا و پایین میرود.

تنظیم اندازه دریچه تخلیه: اولین وظیفه سیلندر هیدرولیک پایینی، تنظیم موقعیت بالا و پایین شفت اصلی است که در نتیجه فاصله بین مخروط متحرک و آستر مخروط بیرونی را تنظیم میکند. هرچه فاصله کمتر باشد، دانهبندی تخلیه سنگشکن کمتر است؛ هرچه فاصله بیشتر باشد، دانهبندی تخلیه سنگشکن بیشتر است. در عین حال، انتخاب انواع مختلف حفره خردایش و غلافهای خارج از مرکز مختلف نیز میتواند اندازه تخلیه مواد را تغییر دهد.

4. ویژگی های سنگ شکن مخروطی هیدرولیک تک سیلندر

مصرف کم قطعات سایشی و هزینه عملیاتی پایین.

خردایش درشت و ریز فقط با تعویض مخروط ثابت قابل انجام است.

نسبت خردایش بزرگ و راندمان تولید بالا.

لایه لایه و شکسته، اندازه ذرات محصول نهایی یکنواختتر است.

فناوری پیشرفته هیدرولیک، محافظت در برابر اضافه بار و تنظیم هیدرولیکی دریچه تخلیه را محقق میکند که ساختار سنگ شکن را ساده کرده و وزن آن را کاهش میدهد.

روانکاری با روغن رقیق، قابل اعتماد و پیشرفته، عمر مفید را بهبود میبخشد.

نگهداری آسان، بهره برداری و استفاده راحت.

معرفی شرکت شیلونگ

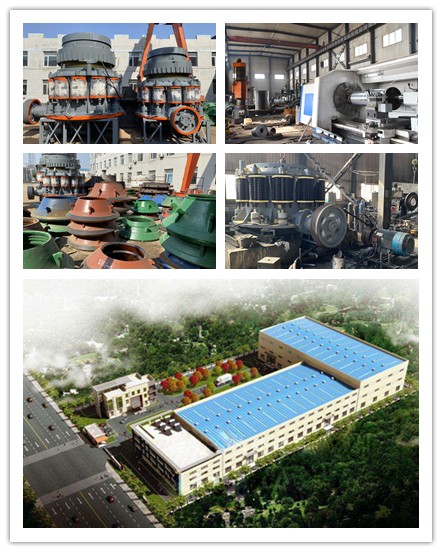

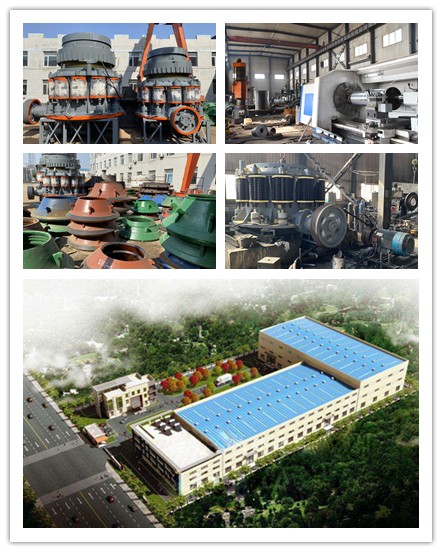

شرکت تولیدی مکانیکی شنیانگ شیلونگ، با مسئولیت محدود. در سال ۲۰۰۰ تأسیس شد. این یک شرکت جامع است که به تولید ماشینآلات معدنی و قطعات یدکی اختصاص دارد.

شیلونگ، به عنوان یک شرکت تولیدی با تمرکز بر تجهیزات و محصولات معدنی، متعهد به ساخت یک کارخانه تولیدی حرفهای جهانی است. شیلونگ دارای بیش از 300 دستگاه تراش، ماشین بورینگ، ماشین فرز و تجهیزات مختلف پردازش سی ان سی است و بیش از 30 پرسنل حرفهای و فنی دارد! انبار بزرگ با مساحتی نزدیک به ۳۰۰۰ متر مربع.

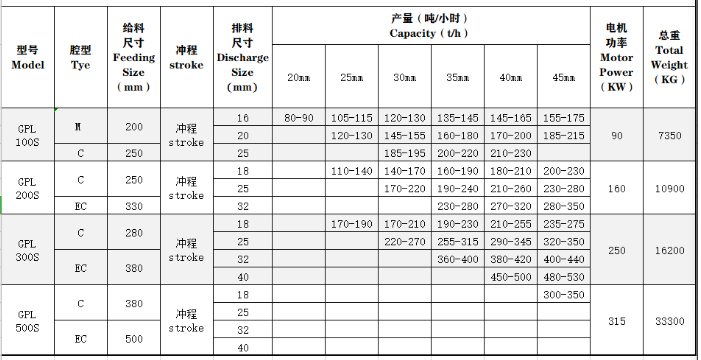

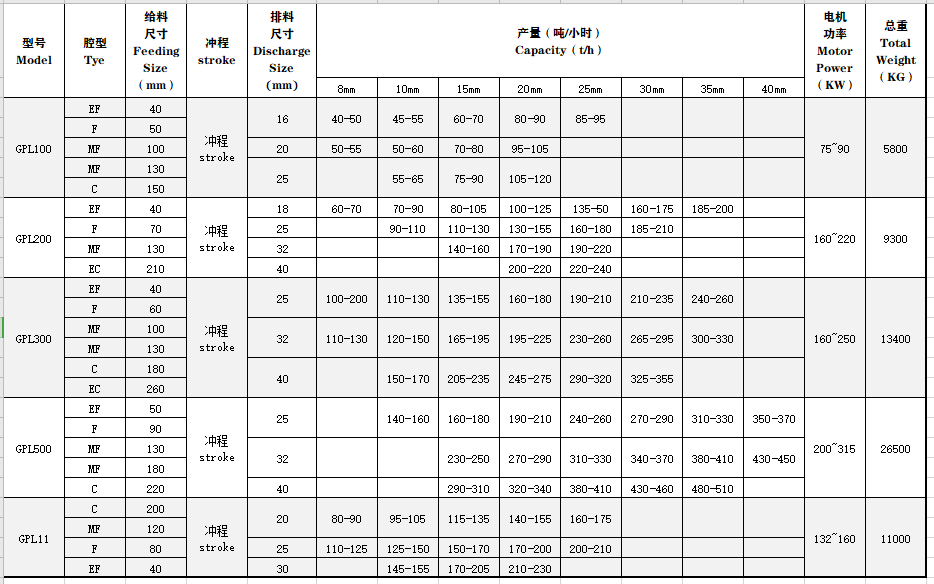

به مدت 20 سال، شیلونگ بیش از 1000 نوع تجهیزات معدن و قطعات نیزه مرتبط را برای بیش از 3000 شرکت داخلی و شرکت تجارت خارجی تولید کرده است. این محصولات عمدتاً ... سنگ شکن مخروطی هیدرولیک چند سیلندرسنگ شکن مخروطی هیدرولیک سنگین سنگ شکن مخروطی هیدرولیک تک سیلندر، سنگ شکن مخروطی سیمونز، سنگ شکن فکی، سنگ شکن ژیراتوری، آسیاب گلولهای، آسیاب غلتکی فشار بالا و قطعات نیزه آنها.

کیفیت محصول قابل اعتماد است، عملکرد خوبی دارد و تحسین گستردهای را به خود جلب کرده است.

شیلونگ مشتاقانه منتظر همکاری با شماست تا آینده را با هم بسازیم!

شرکت شیلونگ بسته بندی و حمل و نقل

شیلونگ به بستهبندی اهمیت زیادی میدهد، بهخصوص محصولاتی که برای تجارت خارجی صادر میشوند.

قبل از بستهبندی، ما تمام قطعات مکانیکی را به دقت بررسی و کنترل خواهیم کرد تا میزان خرابی محصولات به حداقل برسد.

برای حمل و نقل، ما میتوانیم تمام نیازهای حمل و نقل مشتریان خود را برآورده کنیم.

هدف نهایی شیلونگ ساخت یک کارخانه تولیدی حرفه ای در سطح جهانی است. ما برای این هدف خستگی ناپذیر تلاش خواهیم کرد.

شرکت شیلونگ فروشگاه قطعات یدکی

شیلونگ محصولات آماده و تکمیلشدهای را در انبار خود دارد که مساحتی نزدیک به ۳۰۰۰ متر مربع را در بر میگیرد. ما میتوانیم مستقیماً ارسال کنیم و دوره تولید را حذف کنیم.

برای قطعات سنگ شکن فکی، ما میتوانیم سنگ شکن فکی تک ضامنه، سنگ شکن فکی دو ضامنه، سنگ شکن فکی سری c مستو، شفت سنگ شکن فکی، فک متحرک سنگ شکن فکی، بلبرینگ سنگ شکن فکی، صفحه ضامن سنگ شکن فکی، نشیمنگاه صفحه ضامن سنگ شکن فکی، صفحه فک ثابت سنگ شکن فکی، چرخ طیار سنگ شکن فکی، قاب سنگ شکن فکی، میله تنشن سنگ شکن فکی و غیره تولید کنیم.

برای قطعات خردکن مخروطی، ما میتوانیم سنگ شکن مخروطی سیمونز، سنگ شکن مخروطی فنری، سنگ شکن مخروطی سری پزشک عمومی، سنگ شکن مخروطی سری اچ پی، سنگ شکن مخروطی کوپوند، سنگ شکن ژیراتوری و قطعات یدکی آنها از جمله: قاب اصلی سنگ شکن مخروطی، آستر قاب اصلی سنگ شکن مخروطی، شفت متقابل سنگ شکن مخروطی، بوش شفت متقابل سنگ شکن مخروطی، جعبه شفت متقابل سنگ شکن مخروطی، واشر رانش سنگ شکن مخروطی، سوکت سنگ شکن مخروطی، آستر سوکت سنگ شکن مخروطی، حلقه آب بندی سوکت سنگ شکن مخروطی، پینیون خردکن مخروطی، قرقره سنگ شکن مخروطی، شفت اصلی سنگ شکن مخروطی، وزنه تعادل سنگ شکن مخروطی، خارج از مرکز سنگ شکن مخروطی، بوش خارج از مرکز داخلی سنگ شکن مخروطی، بوش خارج از مرکز خارجی سنگ شکن مخروطی، صفحه پله سنگ شکن مخروطی، توزیع کننده تغذیه سنگ شکن مخروطی، فنر سنگ شکن مخروطی، چرخ دنده سنگ شکن مخروطی، چرخ دنده تنظیم سنگ شکن مخروطی، جعبه محرک تنظیم سنگ شکن مخروطی، موتور هیدرولیک سنگ شکن مخروطی، حلقه تنظیم سنگ شکن مخروطی، کلاهک تنظیم سنگ شکن مخروطی، سر سنگ شکن مخروطی، مقعر سنگ شکن مخروطی، پوشش سنگ شکن مخروطی، سیلندر کمکی سنگ شکن مخروطی، کلاهک مهره شفت خردکن مخروطی، کاسه سنگ شکن مخروطی، مخروط تغذیه سنگ شکن مخروطی، قیف سنگ شکن مخروطی، سنگ شکن مخروطی حلقه بافل، سیستم روانکاری سنگ شکن مخروطی و غیره.

برای قطعات آسیاب گلولهای، ما میتوانیم آسیاب گلولهای، چرخدنده آسیاب گلولهای، پینیون آسیاب گلولهای، کوپلینگ آسیاب گلولهای، شفت آسیاب گلولهای، کاهنده سرعت آسیاب گلولهای، پوسته آسیاب گلولهای، بوشهای آسیاب گلولهای، بلبرینگ آسیاب گلولهای، نشیمنگاه بلبرینگ آسیاب گلولهای، تغذیهکننده آسیاب گلولهای، درپوش تغذیهکننده آسیاب گلولهای، حلقه آببندی آسیاب گلولهای، تخلیه آسیاب گلولهای، درپوش تخلیه آسیاب گلولهای، پوشش بلبرینگ آسیاب گلولهای و غیره تولید کنیم.

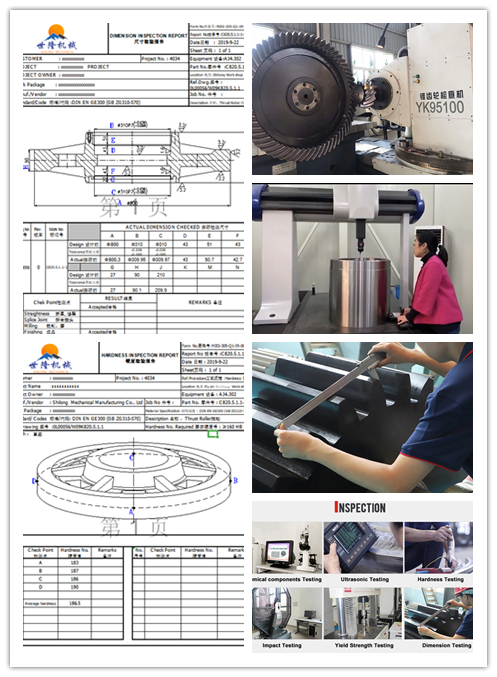

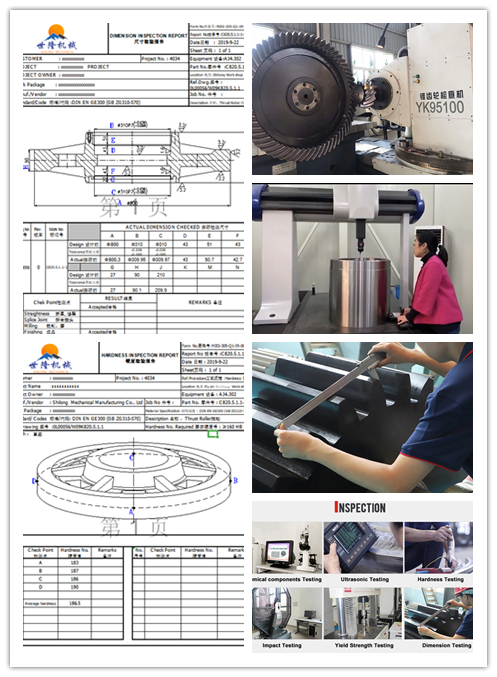

شرکت شیلونگ بازرسی

شیلونگ بیش از 20 سال تجربه در زمینه قطعات یدکی سنگ شکن و آسیاب دارد. برای بازرسی محصول، شیلونگ از همه میخواهد که اصل یک بازرسی برای هر محصول و یک شماره برای هر محصول را اجرا کنند. برای هر محصول کارخانه، یک پرونده مستقل و ردیابی پس از فروش وجود دارد. ما امیدواریم که کنترل کیفیت را در هر جزئیات انجام دهیم.

برای هر محصول، ما بازرسی کیفیت دقیقی انجام میدهیم و پروندههای محصول را تشکیل میدهیم. پس از اتمام بازرسی کیفیت، گزارش بازرسی کیفیت دقیقی ارائه میدهیم.

ما امیدواریم که بتوانیم این کار را واقعاً انجام دهیم: شیلونگ فقط محصولات با کیفیت بالا تولید میکند. و تمام محصولات تولید شده توسط شیلونگ باید محصولات با کیفیتی باشند.